Chocolate tempering machine

The chocolate tempering machine process induces the correct fat and size crystals in the chocolate. How this process is undertaken affects the glossy appearance, the snap, and the heat resistance of the product. Well-tempered chocolate gives a great appearance, snap and luscious consistency

Continuous tempering machine is an automatic thermostat designed according to the characteristics of natural cocoa butter. By strictly controlling the temperature, the crystal is evenly arranged, so that the chocolate product is easy to demould, has a good taste, and is not easy to produce oil separation when the temperature changes, which is conducive to long-term preservation.

Functions

- Chocolate temper is designed to provide the cocoa butter with appropriate crystal structure.

- It is a vertical structure. Chocolate pieces are fed from the side and then rise

Output through ten plates and the top of the machine. The tank is separated

into four temperature sections, with a total of 10 plates. Through this process, chocolate paste with be with smooth taste, bright surface, and longer shelf life.

Advantages

- The automatic chocolate tempering machine is compact, easy-access and convenient installation and maintenance.

- Plates, cover, main frame, heating water tank is stainless steel 304, impellers are copper, electric components are Schneider or Siemens. PLC with touch screen is Siemens, water pump is Grundfos, the temperature controller is Omron.

- Industrial chocolate tempering machine is used in chocolate factory or plant, it is automatic, continuous.

Technical Data:

| Model | MET250 | MET500 | MET1000 | QT2000 |

| Production Capacity(kg/h) | 250 | 500 | 1000 | 2000 |

| Whole Machine Power(kw) | 8.3 | 10.57 | 15 | 18.5 |

| Machine Weight(kg) | 580 | 880 | 1200 | 1500 |

| Outside Dimension(mm) | 1100*800*1900 | 1200*1000*1900 | 1400*1200*1900 | 1700*1300*2500 |

Chocolate Tempering & Processing Machine

Professional Chocolate Tempering & Enrobing System for Perfect Results Every Time

Our Chocolate Tempering & Processing Machine is a high-precision, multi-functional system designed for melting, tempering, and maintaining chocolate at optimal crystallization temperatures. This machine ensures perfectly tempered chocolate with a glossy finish, crisp snap, and extended shelf life, making it ideal for chocolatiers, bakeries, confectionery manufacturers, and commercial kitchens.

Key Benefits

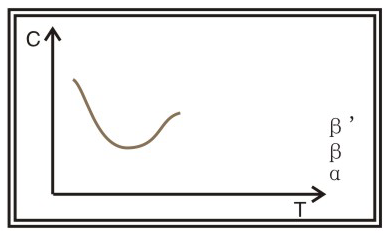

1. Precision Tempering – Ensures Type V beta crystals for superior texture & shine.

2. Multi-Functional – Supports melting, tempering, holding, and enrobing.

3. Automated Control – Digital thermostat with ±0.5°C accuracy.

4. Energy Efficient – Insulated tank reduces heat loss & power consumption.

Key Features

1. Advanced Tempering Technology

- Multi-Stage Temperature Control – Precisely melts, cools, and reheats chocolate for perfect crystallization.

- Automatic Agitator – Prevents scorching & ensures even heat distribution.

- Fast Tempering Cycle – Ready in 20–30 minutes (depending on batch size).

2. Multi-Functional Processing

- Molding – Perfect for chocolate bars, bonbons, pralines, and hollow figures.

- Enrobing – Uniformly coats nuts, biscuits, fruits, and cakes.

- Hand-Dipping – Ideal for strawberries, cookies, and truffles.

3. User-Friendly Operation

- Touchscreen Control Panel – Easy temperature adjustments for dark (31–32°C), milk (29–30°C), and white (28–29°C) chocolate.

- Removable Tank – Easy cleaning & refilling (capacities from 5kg to 200kg+).

- Real-Time Monitoring – Displays temperature & viscosity for optimal results.

4. Industrial-Grade Construction

- Stainless Steel Body – Corrosion-resistant & easy to sanitize.

- Insulated Heating System – Maintains stable temperature with minimal energy use.

- Overheat Protection – Prevents chocolate from burning.

5. Customizable Options

- Automatic Chocolate Pump – For direct transfer to depositors or enrobing lines.

- PLC Integration – Connects with automated production systems.

- Extended Capacity – Custom tank sizes available.

Applications

1. Artisan Chocolate Production – Handmade truffles, bars, and decorations.

2. Commercial Bakeries – Cake coatings, drizzles, and molded chocolates.

3. Industrial Confectionery – High-volume enrobing and molding lines.