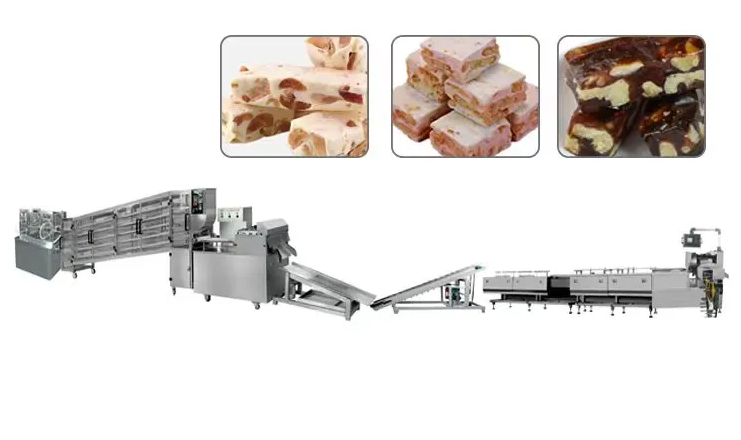

Nougat Production Line

Chocolate Bars/Caramel Nougat Bar/Candy Bar/ Cereal Bars Making Machine /Compound Candy Bar Automatic Production Machine

According to the actual needs of domestic and foreign candy factories, this machine introduces the advanced technology of foreign machinery to manufacture a new generation of complete assembly line production equipment for peanuts, sesame and milk candy. The whole machine is composed of four parts: feed conveying, tablet pressing machine, cooling conveying cabinet and pelleting forming machine. It is equipped with variable frequency speed regulation control, with reasonable structure, operation and maintenance. It is an ideal equipment for candy production today, such as (square and rectangular) milk candy, nougat, peanut candy, sesame candy, bubble candy, etc.

Production Process

Feeding and conveying → Tablet pressing machine → Cooling and conveying cabinet → Granulation molding machine

MAIN TECHNICAL PARAMETERS:

| Capacity | 200-400pcs/min |

| Motor Power | 5.25kw, 380v |

| Produced Size | L(10-150)*W(20-70)*H(5-15) |

| Machine Size | 11130*1000*1700mm |

| Composite wrapping paper thickness | 0.04mm |

| Wrapping material | OPP,PVC,OPP/CPP,PT/PE and so on |

Candy Bar Forming & Energy/Nougat/Muesli/Protein Bar Production Line – Complete Automated System

Our Candy Bar & Nutritional Bar Production Line is a high-performance, fully integrated manufacturing solution designed for mass production of chewy, crunchy, and layered bars including:

Energy & protein bars

Granola & muesli bars

Nougat & cereal bars

Chocolate-coated or fruit-filled bars

This turnkey system handles mixing, forming, cooling, cutting, enrobing (optional), and packaging with outputs up to 2,000 bars/hour, ensuring consistent quality and flexibility for various recipes.

Key Components & Features

1. Automatic Mixing & Preparation System

Twin-Screw Cooker/Extruder: Precise temperature control for nougat, caramel, or protein bases

Dry Blending Station: Uniform mixing of cereals, nuts, seeds, and inclusions

Liquid Ingredient Dosing: Automated syrup, binder, and flavor injection

2. Forming & Shaping Section

Continuous Forming System: Adjustable thickness (5-30mm) and width (20-100mm)

Layered Bar Capability: Up to 3 distinct layers (e.g., cereal base + fruit filling + coating)

Depositing Molds: For specialty shapes (round, square, custom logos)

3. Cooling & Setting Tunnel

Multi-Zone Refrigeration: Gradual cooling to prevent cracking (adjustable 4°C to 25°C)

Non-Stick Conveyors: Food-grade belts with easy-release coatings

4. Precision Cutting Unit

Ultrasonic or Blade Cutting: Clean, crumb-free cuts (length adjustable from 30-150mm)

Scrap Recovery System: Recycles excess material automatically

5. Optional Enrobing & Decoration

Chocolate Coating: Bottom/top/full coverage with tempered chocolate

Sprinkling Station: Adds nuts, seeds, or drizzle patterns

6. Automated Packaging

Flow Wrapping: For individual bars (up to 60 packs/minute)

Boxing/Pouching: For multipacks or bulk quantities

Quality Control: Metal detection, checkweighing, and vision inspection

Unique Advantages

✅ Recipe Versatility: Handles sticky nougat to crunchy granola with quick changeovers

✅ Precision Control: Digital monitoring of viscosity, temperature, and weight

✅ Hygienic Design: CIP (Clean-in-Place) options available

✅ Waste Reduction: <2% material loss with advanced recovery systems

Applications

Sports Nutrition: High-protein bars, keto-friendly bars

Breakfast Bars: Oats, muesli, and fruit combinations

Indulgent Treats: Chocolate-enrobed caramel nougat bars

Functional Foods: Vitamin-fortified or fiber-rich bars

Upgrade your bar production with unmatched efficiency and flexibility!

(Keywords: Cereal bar machine, protein bar production line, nougat forming system, energy bar equipment, muesli bar manufacturing.)