Flow Packing Machine

- Flow packing machine, chocolate bar packing machine is with compact structure, stable function and simply operate.

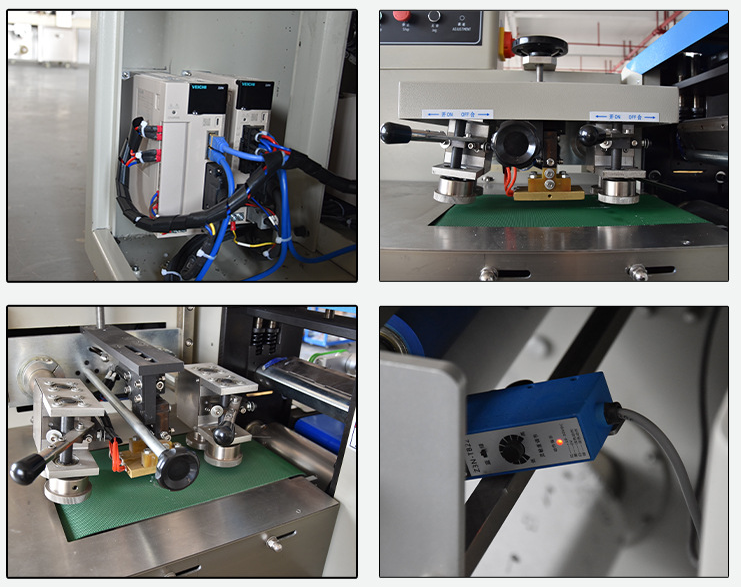

- Double frequency converter controller length of package will cut immediately once setting, adjustment needless, saving time and film.

- It adopts imported electric appliance, touch man-machine interface, convenient parameter setting.

- Self-checking function, troubles can be read easily.

- High sensor photoelectric color charttracking, make the cutting position more correctly.

- Independent temperature PID controlling suitable for various materials of packaging membrane.

- Position stop function, no adhesive and no waste of membrane.

- Clean rotation system, more reliable operation and more convenient maintenance.

- All the controlling operates by the software, convenient for function adjusting and technology upgrading.

- The wrapping machine is used for packing disposable tableware, suitable for packaging paper towels, plastic knives, forks, spoons, toothpicks, wet wipes, chopsticks, straws, food etc. Customized automatic feeding.

Technic Data:

| Model | 350B | 350D |

| Film width | Max.350mm | |

| Bag length | 130~320mm | 180~440mm |

| Bag width | 50~160mm | |

| Product height | Max. 45mm | Max. 60mm |

| Film roll diameter | Max.320mm | |

| Packing speed | 40~230 bag/min. | |

| Power supply | 220V,50/60HZ,2.6KVA | |

| Machine size | (L)4020X(W)770X(H)1450 | |

| Machine weight | 850Kg | |

Automatic Horizontal Flow Packing Machine for Cookies, Wafers, Cereal Bars

——High-Speed, Multi-Purpose Packaging Solution

Professional Packaging for Snack Foods & Nutrition Bars

Our Automatic Horizontal Flow Wrapping Machine is engineered for precision packaging of various dry snacks including cookies, wafers, biscuit sticks, cereal bars, muesli bars, and protein bars. Featuring advanced servo control and customizable settings, it delivers airtight, tamper-evident sealed packs with superior efficiency for modern production lines.

Key Features & Benefits

1. Multi-Product Compatibility – Handles hard cookies, fragile wafers, sticky cereal bars (5-150g/piece).

2. High-Speed Performance – Up to 200 packs/minute (speed depends on product length).

3. Precision Sealing – Servo-driven hot-knife/crimp sealing ensures airtight, wrinkle-free finishes.

4. Gentle Product Handling – Adjustable pushers/vibrating feeders prevent breakage.

5. Smart Operation – 10″ touchscreen HMI with recipe memory for quick changeovers (<3 mins).

6. Hygienic Design – 304 stainless steel contact parts + IP65 protection for food safety.

7. Eco-Friendly Option – Compatible with recyclable/biodegradable films (PLA, OPP, BOPP).

Applications

▸ Biscuits & Cookies – Sandwich cookies, butter biscuits

▸ Wafers & Cones – Delicate wafer sticks, ice cream cones

▸ Nutrition Bars – Protein bars, granola bars, muesli squares

▸ Cereal Snacks – Puffed rice bars, oat clusters

Customization Options

Multi-Lane Feeding (2-5 lanes for small items)

Gas Flushing (MAP for extended shelf life)

Vision Inspection (print registration, defect detection)

Request a Free Test Run!

☎️ +86-13071910582

📧 sales@melechine.com

Keywords:

cookie flow pack machine, wafer horizontal wrapper, cereal bar packaging equipment, automatic biscuit wrapping machine, high-speed snack packaging line, food-grade flow packer, protein bar sealing machine.

Note: Supports pillow pack, gusseted pack, and custom bag shapes.