Candy Bar Machine

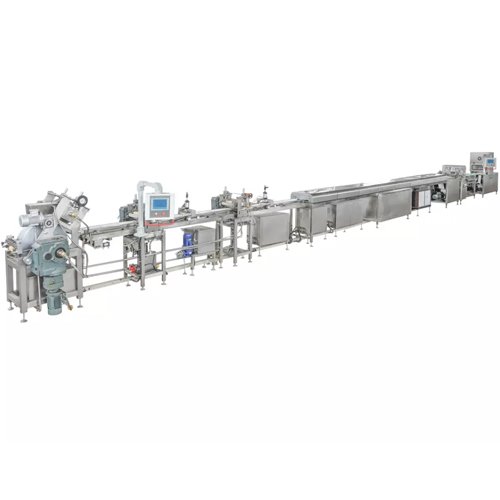

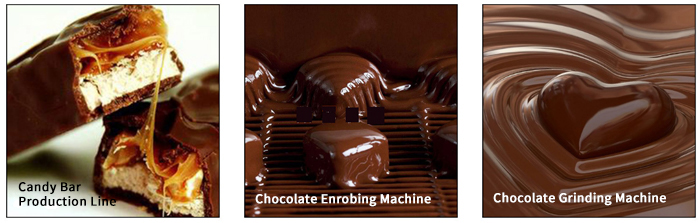

Automatic Candy Bar Production Line is used for every kinds of bar items composed of nougat, nuts, caramel, dry fruits, with or without coating chocolate. It is mainly used to cut Cereal Bar, Protein Bar, Rice Candy, Shaqima, Crispy egg cake, Crispy corn cake, Melon Seeds Cake and Crispy Black Rice Cake.

This candy bar machine includes the following parts:

- Compound group roller

- Particles spreader

- Flattening roll

- Cooling tunnel

- Longitudinal cutter

- Longitudinal distribution

- Latitudinal cutter

- Turning conveyor

- Chocolate enrober

Technic Data:

| Condition | New |

| Applicable Industries | Food Plant, Food & Beverage Factory |

| After Sale Service | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | Motor |

| Voltage | customized |

| Power | 4.5kW |

| Dimension(L*W*H) | 4200*1250*2050mm |

| Weight | 950KG |

| Certification | CE and ISO9001 |

| Warranty | 1 Year |

| Technical Support | Video technical support |

| Application fields | Snack food factory |

| Machinery Function | make cereal bars |

| Raw material | Nuts, chocolate |

| Output product name | candyl bar |

| Key Selling Points | High Productivity |

| Product name | candy bar production line |

| Template size | 400*300*30mm |

| Transmission bandwidth | 400mm |

| Production speed | 8-10molds/min |

| Production line speed | 2.4m/min |

| MOQ | 1 Set |

| Package | Wooden Case |

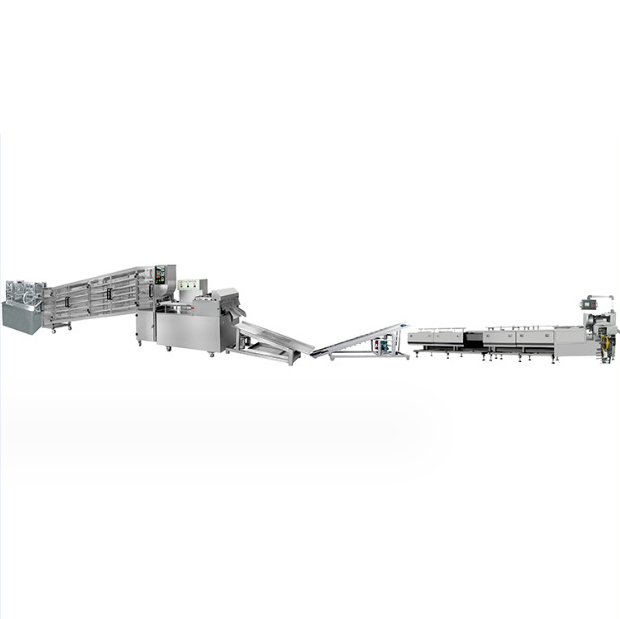

Automatic Compound Candy Bar Line / Energy Bar Production Line

The Automatic Compound Candy Bar Line (also known as Energy Bar Production Line) is a high-efficiency, intelligent food processing system designed for the automated production of composite candy bars, energy bars, nut bars, granola bars, and other nutritional snack products. This fully integrated production line combines mixing, forming, cutting, cooling, and packaging processes, ensuring large-scale, high-standard manufacturing for food processing enterprises.

Key Features:

- Fully Automated Operation – From ingredient mixing to final packaging, the entire process is automated, minimizing manual intervention and maximizing productivity.

- Multi-Ingredient Compatibility – Supports diverse formulations, including chocolate coatings, nut fillings, dried fruits, cereals, and protein blends for customized product variations.

- Precision Forming & Cutting – Advanced molding and cutting systems ensure uniform shape, size, and weight for consistent product quality.

- Energy-Efficient Design – Optimized heating, cooling, and power consumption systems reduce operational costs while maintaining high output.

- Food-Grade Materials – All contact parts are made of SUS304 stainless steel or other FDA/CE-compliant materials for hygiene and easy cleaning.

- Customizable Configurations – Adjustable production speed, mold shapes, and packaging options to meet diverse market demands.

Applicable Products:

- Energy Bars & Protein Bars

- Nut & Seed Bars

- Granola & Cereal Bars

- Chocolate-Coated Candy Bars

- Functional & Nutritional Snack Bars

Technical Advantages:

- Control System: PLC + Touchscreen HMI for precise parameter management

- Versatility: Handles sticky, crunchy, or layered compositions (e.g., syrups, nuts, puffed grains)

Ideal For:

Large-scale food manufacturers, health snack brands, sports nutrition companies, and private-label producers seeking to enhance efficiency, consistency, and scalability.

By integrating this automated production line, businesses can achieve higher output, lower labor costs, and superior product uniformity, ensuring competitive advantage in the growing snack bar market.

Our workshop

Wooden Case Packing and shipping

1.Send us your inquiry

2.Confirmation of the machine type, qty., price, lead time and payment terms

3.We send PI to you

4.Arrange the production after receive your payments

5.Arrange shipment after receiving the balance payments

1.1 year warranty

2.Spare parts support

3.Technical support include drawing, program and installation

4.packaging support to enhance your sales

For single machine, about 25-30 days, for whole production line, about 45-60 days

T/T or L/C