Cereal Bar Production Line

The cereal bar production line is an advanced and continuous line for making all kinds of different shape of cereal bars by mould, like the health bar, cereal bar, peanut candy, sesame candy etc. It is ideal equipment which can produce good quality products with the saving of both the manpower and the space occupied.

There are two types: semi-auto and full-auto lines, include forming unit, vertical cooling tunnel, demould unit and mould conveyor with the heating tunnel.

Technical Data

- The width of candy/cereal slab: 440mm, the width of the conveyor belt for forming line is 600mm, the width of U-shape return conveyor and the chocolate enrobing line is 800mm.

- Capacity:400-700kgs/hour(candy bars)

- Total power: about 200KW.

- The frames, covers and other parts which can be stainless will be ss304 or ss202 (except the standard parts, some frames or parts which couldn’t be ss304 or ss202)

- SEW, Siemens or Chinese famous brands motors.

- Most electric components are Siemens, Omron or Schneider.

Component

Gas cooker

This cooking machine is suit for cooking sugar and glucose. It is necessary equipment for making cooking sugar, glucose etc. It used natural gas for fuel and mixing sugar automatically.

Electricity

- Effective Volume: 200L

- Inner diameter: 830mm

- Height of pot: 600mm

- Cooker time: 50min-1hour/batch

- Size of machine: 1200*1000*1400mm

- Total power: 0.75kw

- Mixing speed: 23 rotate/min

Mixer

It is needed equipment between cooker and cutting machine. The function is to mix peanut and cooked sugar together.

Technical parameters:

- Diameter of pot: Ф400*400

- Capacity:60L

- Voltage: 380v

- Power: 0.75kw

- Heating Power: 1-3kw

- Range: Peanut candy, sesame candy, peanuts and other products of the sugar.

Conveyor lifter

It is used for delivering the mixed sugar and peanut. The length is 3m.

Automatic health/cereal bar making machine

This production line is composed of one hopper, two big flattening rollers, two fans, one slitting cutter set and one left&right cutter set. It is a best and automatically production line for making cereal bar,sesame bar, rice bar, PEANUT BAR, HEALTH BAR etc.

- Production capacity:3000T/8h

- Valid belt width: 500-560mm

- Main Motor Power: 2.2KW

- Hopper power: 1.1kw

- Cutter power: 0.25kw

- Fan power: 0.24kw

- Conveyor power: 0.55kw

- Voltage:380v/50Hz

- Weight:1600KG

- Machine Size:10800*1200*1350mm(length of main forming machine:5800mm,convey:4m)

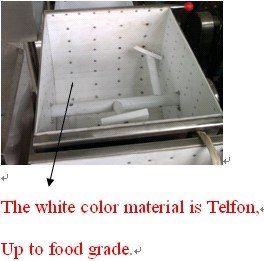

SOME IMPORTANT PARTS PHOTOS:

HOPPER

Roller

First Cutter

SECOND CUTTER

COOLING FANS

COOLING CONVEYOR WITH 4M

Mesh net conveyor(1m,separated adjust speed,can collect crisp)

This mesh net conveyor will be add before the belt cooling convey and after health bar making machine.

It will use mesh net instead of normal belt.so,the crisp waste will be collect before to the packing machine. It will be add the collect plate under the mesh net. The length of mesh net conveyor is 1m. And separated adjust speed.

Cereal Candy Bar Production Line

The Cereal Candy Bar Production Line is a fully automated, high-performance manufacturing system designed for the efficient production of cereal-based candy bars, including granola bars, muesli bars, crispy rice treats, and other nutritious snack bars. This advanced production line integrates mixing, forming, baking (or cooling), cutting, and packaging into a seamless process, ensuring consistent quality, high output, and compliance with food safety standards.

Key Features:

- End-to-End Automation – From ingredient feeding to final packaging, the entire process is automated, reducing labor costs and human error while improving efficiency.

- Versatile Formulation Handling – Compatible with a wide range of ingredients, including puffed cereals, oats, nuts, dried fruits, honey, chocolate coatings, and protein mixes, allowing for diverse product variations.

- Precision Extrusion & Molding – Advanced forming technology ensures uniform bar thickness, shape, and texture, whether producing chewy, crispy, or layered bars.

- Baking/Cooling System – Equipped with adjustable baking tunnels or cooling conveyors to set the bars’ structure while preserving flavor and crunchiness.

- High-Speed Cutting – Servo-driven cutting units deliver clean, precise slices with minimal waste, adaptable to different sizes and shapes.

- Hygienic & Easy to Clean – Constructed with food-grade stainless steel (SUS304) and designed for quick disassembly, meeting FDA, CE standards.

- Customizable Packaging – Compatible with flow wrappers, pouch sealers, or box packaging systems for flexible retail-ready solutions.

Applicable Products:

- Granola & Muesli Bars

- Crispy Rice Cereal Bars

- Oat-Based Energy Bars

- Chocolate-Coated Cereal Bars

- Kids’ Snack Bars (e.g., honey-nut, fruit-filled)

Technical Specifications:

- Control System: PLC + Touchscreen HMI for real-time monitoring and parameter adjustments.

- Heating Options: Electric/gas heating for baking or no-bake cooling systems.

- Optional Add-ons: Chocolate enrober, sprinkler, or multi-layer filling systems.

Ideal For:

- Large-Scale Snack Manufacturers

- Health Food & Organic Brands

- Private-Label Producers

- Breakfast Cereal & Functional Food Companies

Why Choose This Line?

1. Scalable Production – Meet small or bulk orders with consistent quality.

2. Reduced Operational Costs – Minimize waste and energy consumption.

3. Fast ROI – High automation lowers labor dependency and boosts output.