Pillow Packing Machine

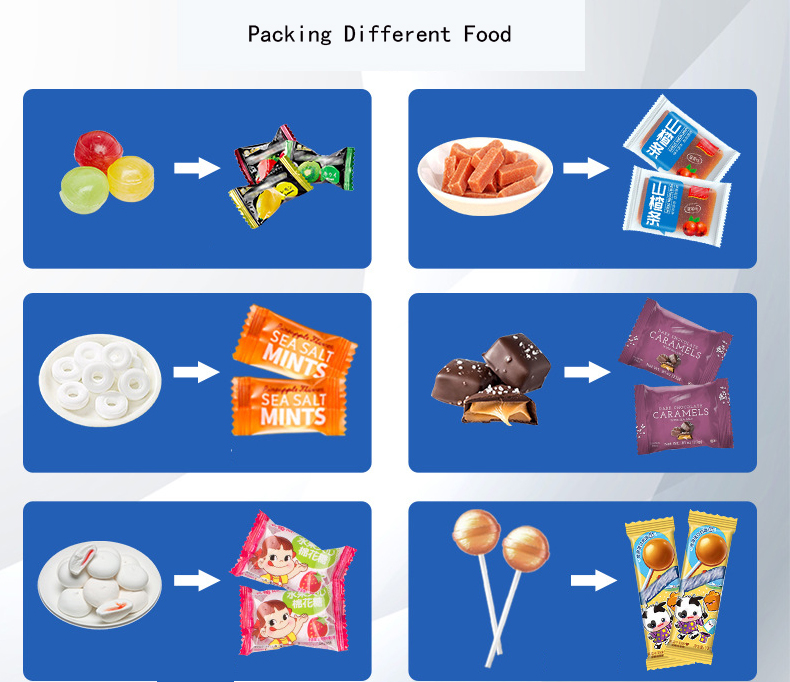

It is applicable to the packaging of solid articles in various shapes, such as biscuits, chocolate, extra long candy, bread, egg yolk pie, instant noodles, ice cream, moon cakes and other foods, medicines, daily necessities, aviation knives and forks, hardware accessories, etc

Full computer control, variable frequency speed regulation, high sensitivity eye tracking, independent control of sealing temperature, suitable for a variety of packaging materials; Simple mechanical structure and convenient maintenance; The whole machine runs smoothly, with little wear and long service life

Character

- Full computer control, photoelectric color code two-way tracking, fast tracking and can effectively eliminate packaging errors, avoid waste of packaging film and materials.

- Intelligent temperature control, intuitive display, convenient setting and accurate temperature control.

- It has the advantages of high speed, high efficiency, stable operation, simple operation, low failure rate and convenient maintenance.

- It can be equipped with automatic date printer, hanging automatic punching device, automatic blanking device, nitrogen filling device, customized stainless steel shell model, etc.

- Cold sealed packaging can be customized (such as ice cream, chocolate, etc.)

Feature:

- Our food packing machine is designed as per European standard, the main components are food-grade stainless steel material

- Our wrapping machine has the advantage of high-speed, good stability, can be used for over 20 years.

Technic Data:

| Item No. | ME-Z401 |

| Packing Speed | 50PCS-400PCS/MIN ( As candy size) |

| Candy Dimension | Length: 12-60MM |

| Width: 12-30MM | |

| Thickness: 5-25MM | |

| Voltage | 220V 60Hz |

| Total Power: | 2.8KW |

| Net weight | 900KG |

| Dimension | 3800x990x1570mm |

| Packing Materials | Single-layer and multi-layer heat-sealable materials such as opp, cpp, pet aluminized film, aluminum plastic film, paper plastic,paper glue,etc. |

| Bag Length | 55-350MM |

| Packing Film Width | 50-200MM |

Automatic Chocolate & Snack Bar Packaging Line

——High-Speed Pillow Pack Solution for Confectionery & Nutrition Products

End-to-End Packaging Automation for Diverse Food Products

Our Automatic Feeding Chocolate Packing Line is an integrated system designed for high-volume packaging of various solid food items, including chocolate bars, wafer sticks, biscuits, cakes, protein bars, and snack bars. This advanced horizontal flow wrap system creates secure, attractive pillow packs while ensuring maximum production efficiency and product protection.

Key Features & Benefits

✔ Multi-Product Versatility – Handles:

Chocolate products (bars, coated wafers)

Bakery items (biscuits, cake slices)

Nutrition bars (protein, cereal, energy bars)

Crispy snacks (wafer sticks, rice crackers)

✔ High-Speed Performance – Processes 100-300 packs/minute (product-dependent)

✔ Precision Packaging – Servo-controlled system ensures:

Consistent lengthwise & cross-seal integrity

Accurate film cutting & positioning (±1mm tolerance)

Adjustable seal pressure & temperature

✔ Gentle Product Handling – Features:

Vibratory/linear feeding system

Anti-crush pusher mechanism

Product spacing control

✔ Smart Operation – 10″ color touchscreen HMI with:

50+ recipe memory

Production counter

Fault diagnostic system

✔ Hygienic Design – 304 stainless steel construction with:

Easy-clean surfaces

IP65 protection grade

FDA/CE/SGS compliance

✔ Sustainable Options – Compatible with:

Recyclable/biodegradable films

Reduced material consumption design

Technical Specifications

Packaging Speed: 100-300 packs/min

Product Dimensions:

Length: 30-250mm

Width: 20-120mm

Height: 5-60mm

Film Width: 150-500mm

Power: 380V/50Hz (220V optional)

Seal Type: Hot knife/crimp (cold seal optional)

Air Pressure: 0.6-0.8MPa

System Components

Automatic Feeding System:

Vibratory bowl feeder

Linear conveyor with product spacing

Horizontal Flow Wrapper:

Servo-driven film transport

Precision sealing jaws

Tension control system

Optional Add-ons:

Checkweigher

Metal detector

Inkjet printer

Vision inspection

Why Choose Our Packaging Line?

✅ 30% Higher Efficiency vs. conventional wrappers

✅ <0.3% Rejection Rate with precision controls

✅ Quick Changeover – <5 minutes for product switching

✅ Future-Ready – Modular design for easy upgrades

Industry Applications

▸ Chocolate Manufacturers – Bars, coated biscuits

▸ Bakery Plants – Biscuits, cake portions

▸ Nutrition Companies – Protein/granola bars

▸ Snack Food Producers – Wafer sticks, cereal clusters

Request Line Demonstration!

📞 +86-13071910582

📧 sales@melechine.com

Keywords:

chocolate pillow pack machine, wafer packaging line, automatic biscuit wrapper, snack bar flow packer, high-speed food packaging equipment, horizontal form fill seal machine, protein bar packaging system.

Note: Custom configurations available for special film types, product shapes, and factory layouts.